Transforming Business with Quality CNC Turning Parts: A Deep Dive into the China CNC Turning Part Manufacturer Landscape

In today’s fast-paced manufacturing environment, precision and efficiency are paramount. As a China CNC turning part manufacturer, DeepMould.net exemplifies excellence through innovation, advanced technology, and an unwavering commitment to quality. In this thorough exploration, we will discuss the journey of CNC (Computer Numerical Control) machining, the intricacies of turning parts manufacturing, and why choosing a reliable partner in China can enhance your business productivity.

Understanding CNC Machining and Turning

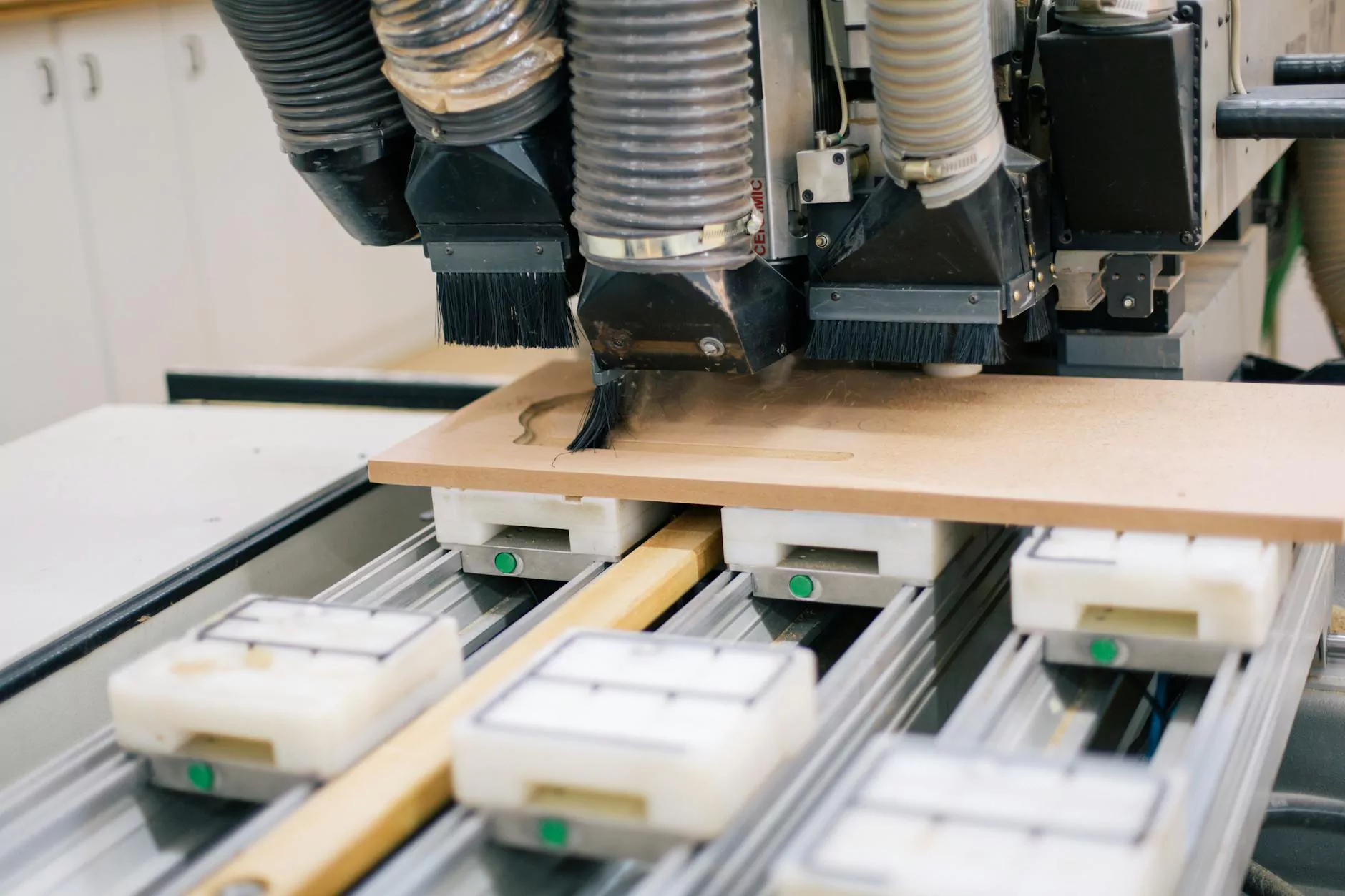

CNC machining is a revolutionary process that automates the control of machining tools through computer programs. It allows manufacturers to produce parts with remarkable accuracy and efficiency. Among the various CNC processes, CNC turning is a key method where the material rotates against a stationary cutting tool to shape the part to the required specifications.

The Advantages of CNC Turning

- High Precision: CNC turning machines can achieve tolerances as tight as ±0.01mm.

- Consistency: Once a part is programmed, it can produce identical pieces repeatedly without deviation.

- Versatility: Capable of working with a wide variety of materials, including metals, plastics, and composites.

- Efficiency: Automated processes reduce production time significantly, ideal for mass production runs.

Why Choose a China CNC Turning Part Manufacturer?

Outsourcing CNC turning parts manufacturing to China can provide several strategic advantages for businesses around the globe. Here are several compelling reasons:

Cost-Effectiveness

Manufacturing in China typically offers lower labor costs and overhead expenses, leading to substantial savings. By partnering with a China CNC turning part manufacturer, your business can allocate funds to other areas such as research and development or marketing.

Access to Advanced Technology

China hosts a plethora of manufacturers that constantly invest in the latest manufacturing technologies. This commitment ensures that products are not only affordable but also utilize superior technology that enhances performance and quality.

Scalability

China’s manufacturing ecosystem supports scalability. Whether you need a small batch of prototypes or large-scale production runs, a proficient China CNC turning part manufacturer can adapt quickly to your needs.

DeepMould.net: A Leader in CNC Turning Parts Manufacturing

DeepMould.net stands out as a premier China CNC turning part manufacturer. With years of experience and expertise, we offer tailored solutions to meet specific client requirements across various industries such as automotive, aerospace, medical devices, and more.

Our Services

We pride ourselves on our comprehensive service offerings that include:

- Prototype Development: We assist clients in refining their designs through rapid prototyping services.

- Custom CNC Turning Parts: Our team specializes in creating parts tailored to unique specifications.

- Quality Assurance: Rigorous testing and inspection processes ensure the products meet international standards.

- Quick Turnaround Times: Our streamlined processes enable efficient production timelines from concept to delivery.

Quality Control at DeepMould.net

Quality is at the heart of our manufacturing philosophy. We understand that even minor defects can lead to significant operational disruptions for our clients. Hence, our operations are governed by stringent quality control guidelines:

Key Quality Assurance Processes

- Material Selection: Only the best materials are chosen to create durable and reliable components.

- In-Process Inspection: Continuous monitoring during manufacturing ensures adherence to quality standards.

- Final Quality Check: All parts undergo rigorous final inspection before they are shipped to clients.

The Future of CNC Turning Part Manufacturing

The future of CNC turning and broader manufacturing is bright, with several trends shaping the industry:

Industry 4.0 and Automation

The integration of smart technology into manufacturing processes enhances operational efficiency. CNC machines equipped with IoT capabilities allow for real-time monitoring and predictive maintenance, reducing downtime and increasing productivity.

Green Manufacturing Practices

As industries become more aware of their environmental impact, adopting sustainable manufacturing practices is becoming essential. At DeepMould.net, we are committed to implementing eco-friendly practices to minimize waste and energy consumption.

Customization and Flexibility

Today's consumers demand customization. Modern CNC machining processes enable the production of bespoke parts that cater to specific client requirements while maintaining cost effectiveness.

Case Studies: Success Stories at DeepMould.net

Our portfolio is rich with success stories that highlight our capabilities as a China CNC turning part manufacturer. Here are a few examples:

Automotive Parts Manufacturing

We partnered with a major automotive supplier to produce precision turning parts essential for engine components. By utilizing our advanced CNC technology, we significantly reduced production costs while improving part reliability.

Aerospace Component Fabrication

In the aerospace sector, where safety and precision are non-negotiable, we worked with a leading aerospace manufacturer to develop critical components that met stringent regulatory standards. Our commitment to quality ensured that their products were not only competitive but also first-rate in performance.

How to Choose the Right CNC Turning Part Manufacturer

With numerous options available, selecting the right China CNC turning part manufacturer can be daunting. Here are some tips to guide your decision:

- Assess Experience: Look for manufacturers with a proven track record in your industry.

- Evaluate Technology: Ensure the manufacturer utilizes the latest CNC technology to guarantee quality and efficiency.

- Check Certifications: Verify that the manufacturer adheres to international quality standards such as ISO 9001.

- Request References: A reputable manufacturer should provide references or case studies to validate their claims.

Conclusion

The value of partnering with a reliable China CNC turning part manufacturer like DeepMould.net cannot be overstated. With cutting-edge technology, a commitment to quality, and an adaptable approach to client needs, we stand ready to support your manufacturing requirements.

By choosing DeepMould.net, you're not just selecting a supplier; you are opting for a dedicated partner in your manufacturing journey. Together, we can achieve remarkable results that propel your business forward.